Pumps

Selecting the Right Chemical Transfer Pump

Factors to Consider

Chemical Compatibility

Ensure the pump materials are compatible with the chemicals being transferred to prevent corrosion and leaks.

Flow Rate & Pressure

Determine the required flow rate and pressure to meet your application needs.

Safety & Regulations

Comply with industry standards and safety protocols to protect workers and the environment.

Types of Chemical Transfer Pumps

Positive Displacement

Pumps that rely on the physical movement of parts to displace fluid.

Centrifugal

Pumps that use rotational force to move fluids through an impeller.

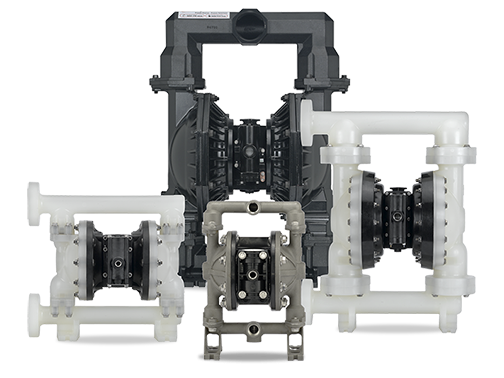

Diaphragm

Pumps that use a flexible diaphragm to create suction and discharge.

Peristaltic

Pumps that use rollers to squeeze fluid through a flexible tube.

Positive Displacement Pumps

Gear Pumps

Two gears that mesh to move fluid through the pump.

Lobe Pumps

Two rotating lobes that create suction and discharge.

Piston Pumps

Use a piston to draw in and expel fluid through the pump.

Centrifugal Pumps

Impeller Design

The impeller shape and materials affect the pump’s performance and durability.

Self-Priming

Some centrifugal pumps can automatically re-prime, reducing the need for manual intervention.

Corrosion Resistance

Careful material selection is crucial to prevent corrosion in chemical applications.

Pump Materials & Compatibility

Stainless Steel

Excellent corrosion resistance for a wide range of chemicals.

Plastic

Lightweight and cost-effective for certain non-corrosive chemicals.

Specialized Alloys

Tailored for highly aggressive chemicals or extreme temperatures.

Elastomers

Flexible components to seal and protect against leaks.

Flow Rate & Pressure Requirements

Determine Needs

Assess the required flow rate and pressure for your applications.

Select Appropriate Pump

Choose a pump that meets or exceeds your performance requirements.

Verify Compatibility

Ensure the pump materials are suitable for the chemicals being transferred.

Maintenance & Safety

Regular inspections, cleaning, and replacement of worn components are essential for reliable and safe operation.

- Use appropriate personal protective equipment (PPE)

- Follow industry guidelines and safety regulations

- Implement emergency response plans for spills or leaks