ARO® pumping solutions to improve

your fluid handling productivity

The EVO Series™ represents a significant advancement in pumping technology from the established ARO® brand, leveraging nearly a century of experience in this field. Building upon the success of the industry-leading EXP Series Air Operated Diaphragm pumps, ARO® has incorporated a distinctive blend of features from other pump technologies into the EVO Series™. This fusion encapsulates the flexibility of a diaphragm pump alongside the operational efficiency and precision control associated with other positive displacement technologies.

The outcome is an electric diaphragm pump that delivers a unparalleled array of features previously unavailable in a single pump solution. It marks a transformative shift in the capabilities of pumping systems, challenging traditional expectations to redefine what a pump can achieve for users.

EVO Series – Product Overview

- Integrated Encoder

- No Maintenance Gearbox

- Seal-less Design – No dynamic seals that could allow hazardous fluids to enter the environment

- Unique 3 chamber design

- Innovative diaphragm developed exclusively for the EVO Series™ Electric Diaphragm Pump

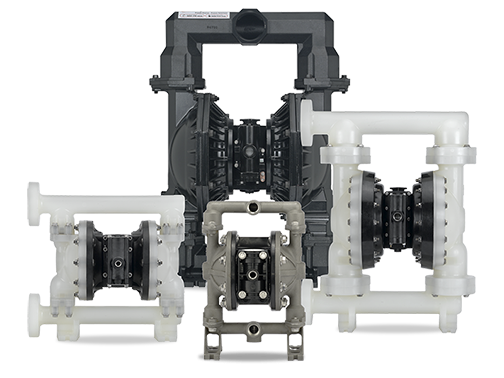

- Choice of 5 different materials of construction to handle the most aggressive and corrosive fluids

- Built in control and monitoring capability

- Can be controlled via a PLC

READY TO EVOLVE YOUR EXPECTATIONS?

WHEN IDEAS EVOLVE INTO REALITY

Designed for Safety

- Deadhead Capability: The EVO Series™ Electric Diaphragm Pump offers effective deadhead protection. Equipped with a built-in encoder, it can detect pumping speed, reduce motor speed, and maintain system pressure for extended durations. Its automated system enables the pump to resume operations without the need for priming and can be programmed for automatic shutdown.

- Leak Detection: Through integrated leak detection, sensors are capable of identifying diaphragm failure and subsequently shutting down the pump to prevent leaks.

- Secondary Leak Containment: To enhance protection, the pump was designed with secondary seals to safeguard the actuation mechanism in case of diaphragm failure.

Designed for Control

- Built-in encoder and Variable Frequency Drive included: Monitor and regulate the pump flow based on your process parameters, encompassing flow, head, torque, and other variables.

Designed for Efficiency

- Maximum energy efficiency: Fully electric pump utilizes a 400V AC gear motor and requires no compressed air system

- Lower repair costs:The integrated monitoring system enables scheduled preventative maintenance, facilitating easy repairs and minimizing downtime.

Designed to Perform

- Lower Pulsation:Thanks to its distinctive three-chamber design, this pump reduces pulsations to a significant extent when compared to traditional two-chamber electric diaphragm pumps.

- Easy to Install:ARO engineers have eliminated the requirement for a base plate or shaft alignment. The EVO Series™ pump features a compact footprint, making it suitable for installation in small operational spaces.

THOROUGH TESTING TO MEET DEMANDING CONDITIONS

The innovative design of the EVO Series™ Electric Diaphragm Pump instills the assurance to safeguard your personnel, sustain seamless operations, and minimize your operational expenses.

ARO engineers subjected the pump to more than 20,000 hours of rigorous testing under full load conditions with diverse fluids. Testing and trials replicated the harshest conditions to ensure that these electric pumps would exceed your most stringent expectations.

The EVO Series™ pump provides an adaptable solution capable of performing across a broad spectrum of applications under the most challenging conditions and requirements.

GET IN TOUCH

Looking for more information regarding the EVO series?

Get in touch with us today for any enquiries