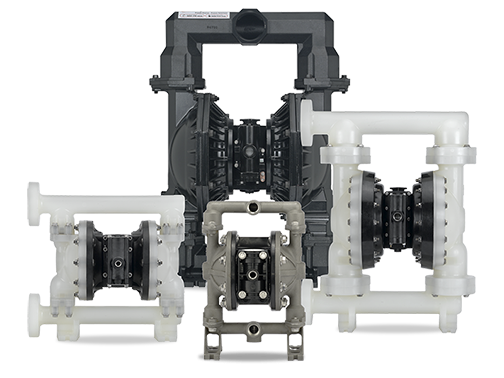

Due to large internal clearances and flap valve options, AODD Pump are commonly used for pumping slurries and solids in suspension. Common examples are Ceramic glazes & slips, Poultry Gizzards, Necks & Livers, and effluent to name but a few.

If the product is left in the pump when not running, at the end of a shift for example, there can be time for the solid to separate from the liquid. A heavier solid will settle to the bottom of the chamber and the lighter fluid will rise to the top.

An AODD without good air control, can start at full pressure slamming the diaphragm and plate into the product. The increased resistance at the bottom of the chamber puts an unbalanced load on the diaphragm which can cause early diaphragm failure, worn shaft bushings and even the bending of a shaft or shaft stud. Particularly on larger pumps.

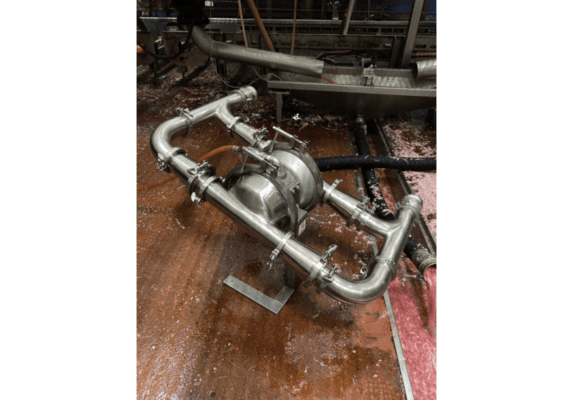

In the example above we can see a poultry pump with a bent shaft stud caused by exactly this problem. Our customer after seeing the damage on a number of occasions asked us for a solution. We had previously developed a soft start pneumatic procedure to start pumps slowly for exactly this problem, pushing the solid back into suspension prior to running at full speed.The solution to the problem is what sets Diaphragm Pumps Ltd above other distributors when it comes to AODD applications. With many years of experience with many brands, we have seen and solved this problem on a number of occasions.

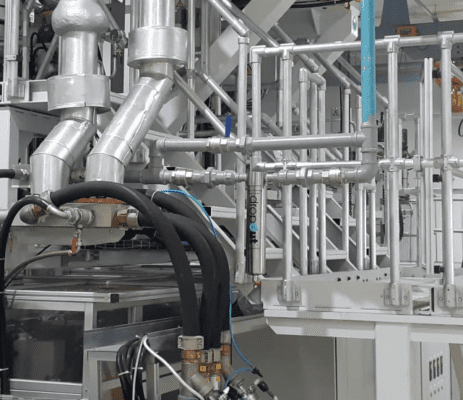

The pneumatic panel with on/off switch, costs less than the price of the diaphragm plate it will protect.