Pumps

ARO Pump Maintenance: 2025 Guide to Keep Your Pumps Running

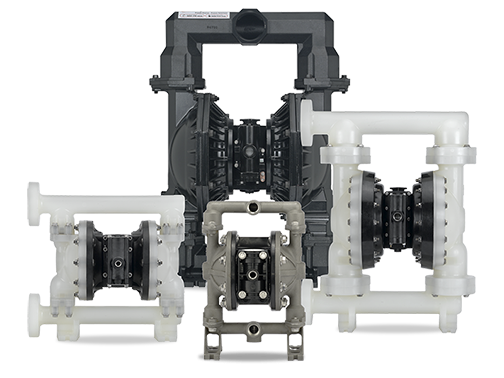

Keeping your pumps in top condition is essential for safety, efficiency, and avoiding costly downtime. That’s why ARO pump maintenance should be a priority for every operator. Whether you run air-operated diaphragm pumps (AODD), electric diaphragm pumps (EODD), or piston pumps, this 2025 guide will help you keep your equipment running smoothly.

Why regular aro pump maintenance matters

- Prevent Downtime – Unexpected failures can halt production.

- Extend Pump Life – Proper care reduces wear on diaphragms, seals, and valves.

- Ensure Safety – Especially when handling hazardous or corrosive chemicals.

- Save Money – Proactive servicing is cheaper than emergency repairs.

💡 Tip: Many ARO pumps are designed for quick servicing with modular parts – a key advantage when planning preventative maintenance.

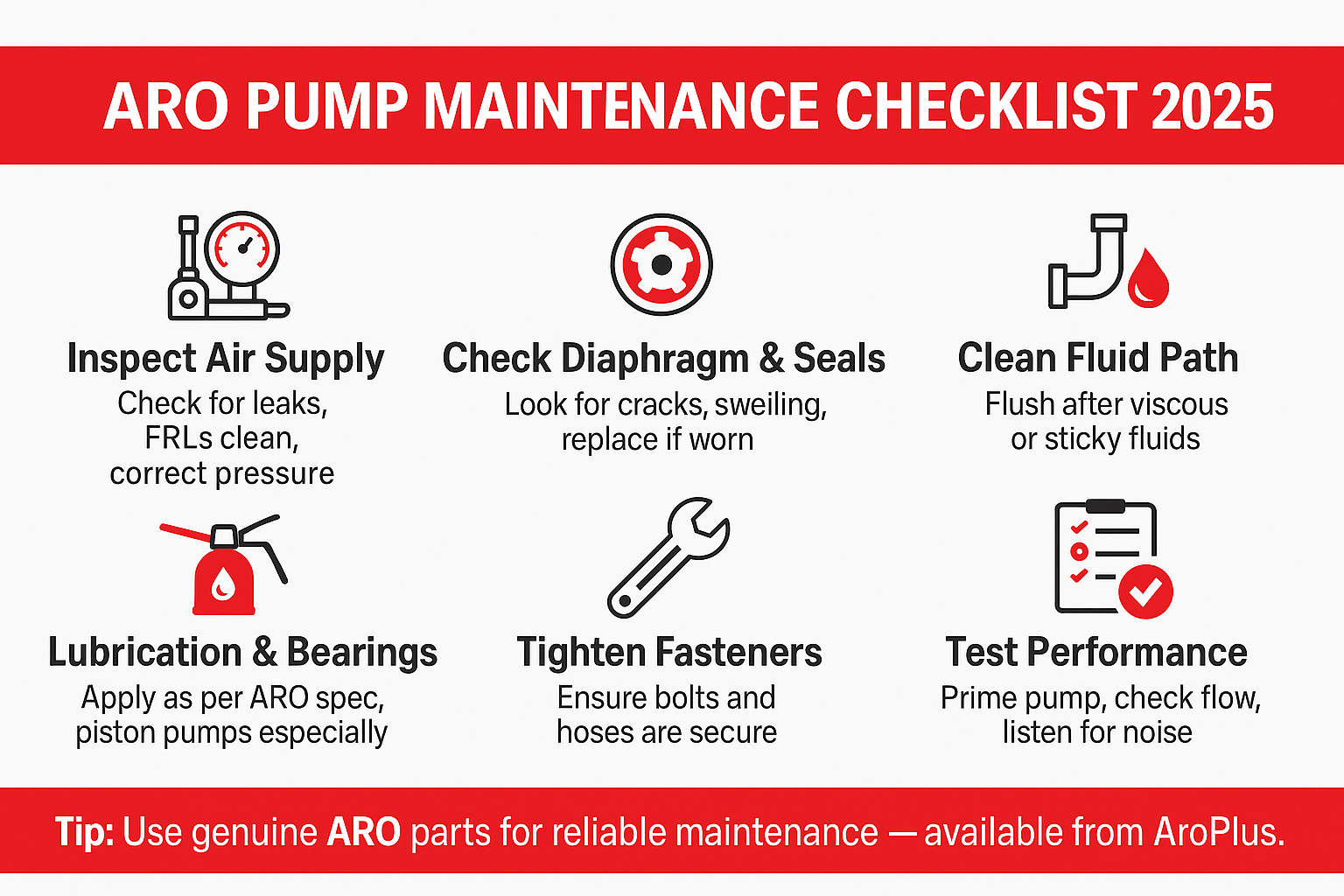

ARO Pump maintenance checklist 2025

Step-by-Step Maintenance Guide

Inspect the Air Supply (AODD/EODD)

- Ensure air lines are free of leaks.

- Check FRL’s (Filters, Regulators, Lubricators) for cleanliness.

- Maintain correct operating pressure as per ARO guidelines.

2. Check Diaphragms and Seals

- Inspect for cracks, swelling, or chemical damage.

- Replace diaphragms at the first sign of wear to avoid leaks.

- Use genuine ARO replacement parts for full compatibility.

3. Clean the Fluid Path

- Flush pumps regularly, especially after handling viscous or sticky fluids.

- For food & beverage or pharma, use approved cleaning solutions.

4. Lubrication and Bearings (Piston Pumps)

- Check manufacturer’s spec for lubrication points.

- Grease bearings at recommended intervals.

5. Tighten Fasteners and Connections

- Tighten bolts to recommended torque.

- Ensure fittings and hoses show no signs of wear.

6. Test Before Returning to Service

- Prime the pump and check flow rates.

- Listen for unusual noises that may indicate internal wear.

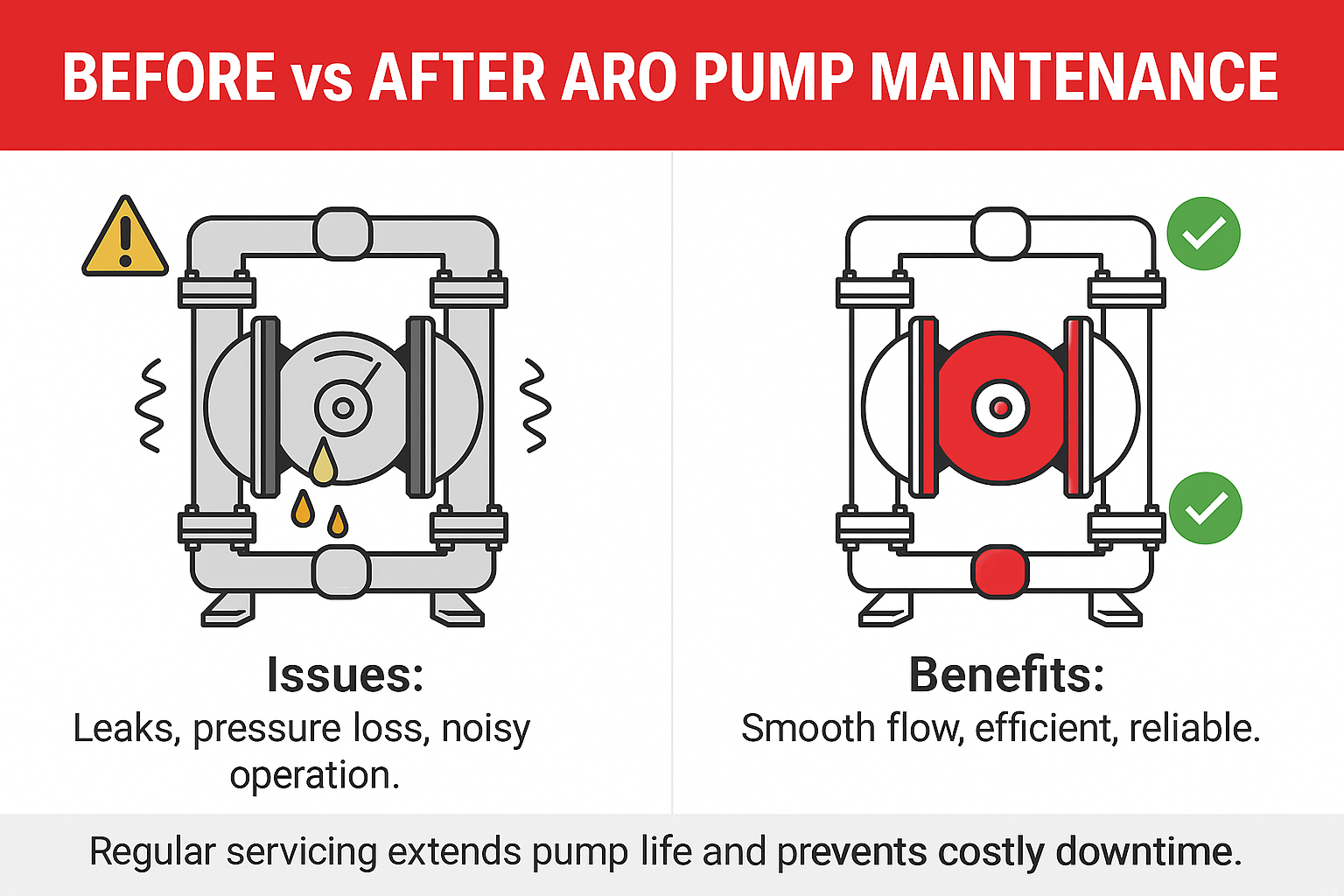

Before vs After Maintenance

When to Schedule Professional Servicing

While operators can handle basic checks, sometimes professional servicing is the safer and smarter option.

Call in ARO specialists if you notice:

- Consistent loss of flow or pressure

- Fluid leakage around pump chambers

- Excessive vibration or noise

- Premature diaphragm or seal failure

💡 AroPlus offers full service and repair support across the UK, ensuring your ARO pumps are maintained to factory standards.

ARO Pump Maintenance Best Practices for 2025

- Use only genuine ARO spare parts to ensure reliability.

- Keep a maintenance logbook to track inspections and part replacements.

- Train operators on correct startup and shutdown procedures

- Invest in preventative maintenance contracts for peace of mind.

Conclusion

Proactive ARO pump maintenance in 2025 means fewer breakdowns, safer operations, and long-term cost savings. Whether you handle chemicals, food, pharmaceuticals, or wastewater, looking after your pumps is an investment that always pays off.