Compressors

The Importance of Compressed Air Quality

The Importance of Compressed Air Quality

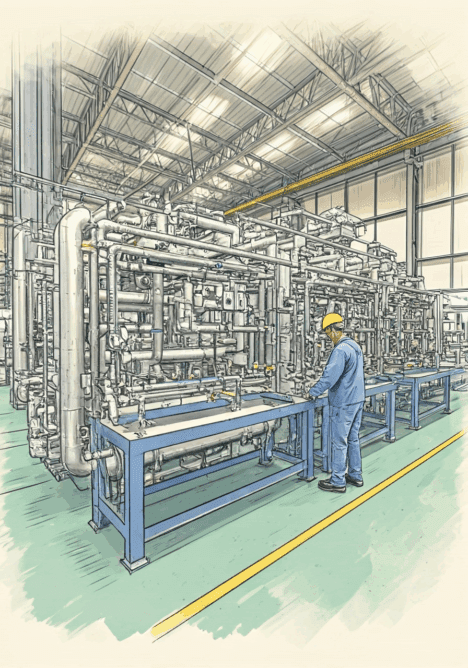

Compressed air is often called the “fourth utility” in industrial settings. Up to 10% of industrial electricity powers air compressors. It’s essential across manufacturing, automotive, food and pharmaceutical industries.

What is compressed air quality?

Critical Applications of Compressed Air

General Manufacturing

Powers pneumatic tools & robotic systems. Drives automated assembly lines.

Automotive

Essential for paint booths, conveyor systems, and robot arms. Ensures consistent quality.

Food & Beverage

Used in mixing, packaging and sensitive operations. Requires highest purity standards.

Pharmaceuticals

Critical for sterile packaging and manufacturing. Subject to strict regulatory oversight.

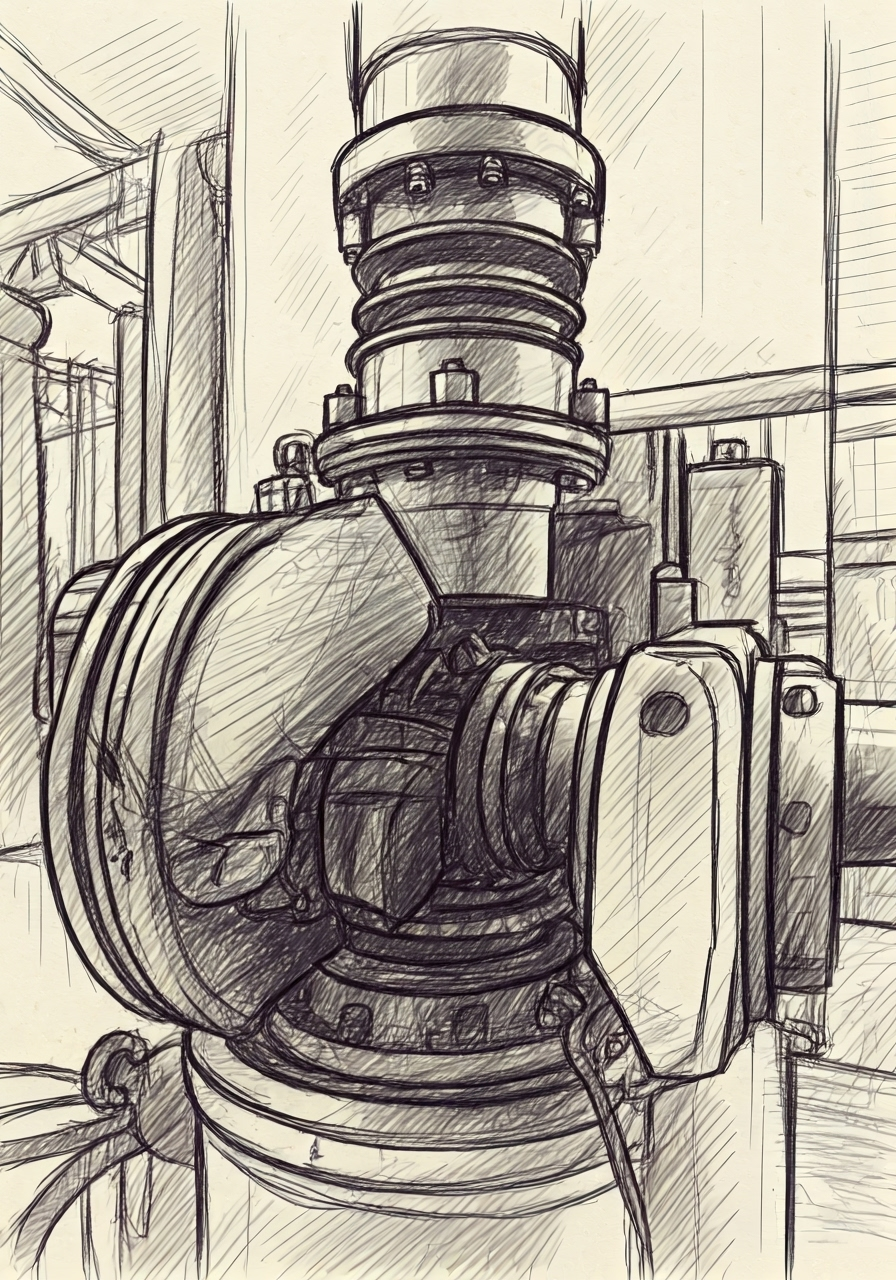

Risks of poor compressed air quality

Product Contamination

Can lead to costly recalls and significant financial losses

Production Standstill

Results in expensive downtime and missed deadlines

Equipment Damage

Causes increased wear and tear on precision machinery

Higher Costs

Requires additional cleaning and maintenance expenses

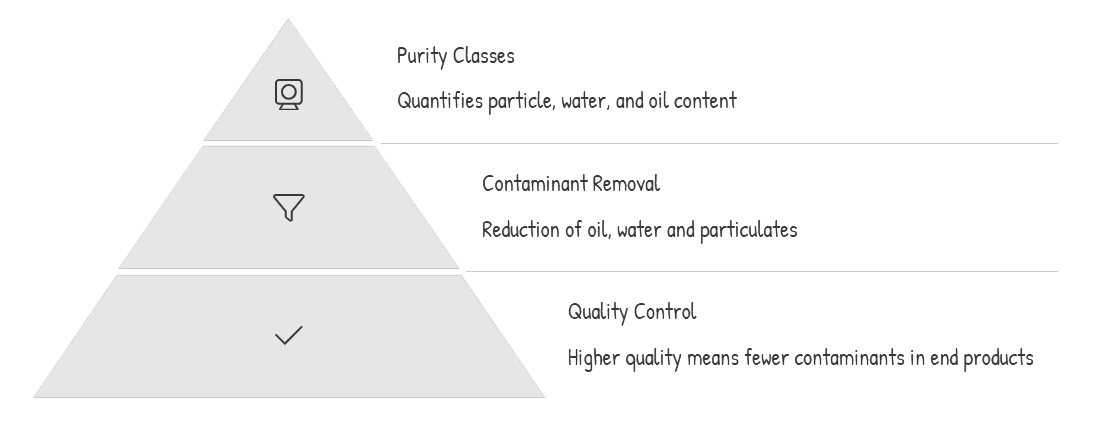

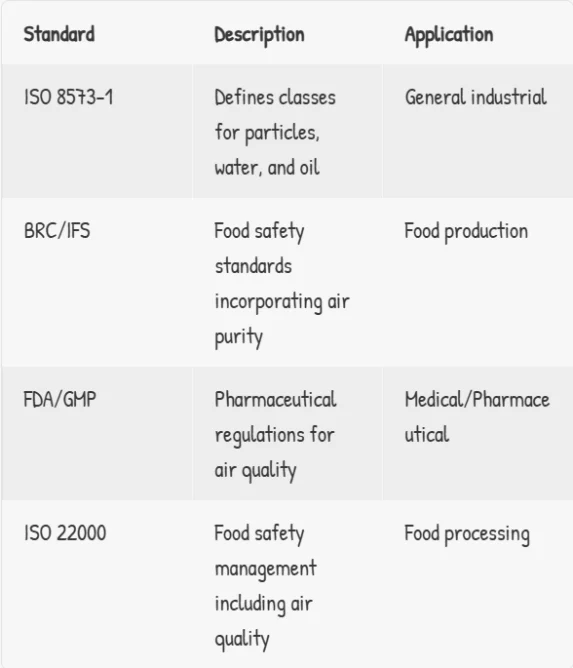

Compressed Air Quality Standards

Industry Case Examples

ensuring and maintaining air quality

Filtration Systems

Multi-stage filters, dryers, and oil separators

Training

Staff education on contamination risks

Monitoring

Regular testing and quality verification

Maintenance

Scheduled service and component replacement

Conclusion: Why Compressed Air Quality Matters

Product Excellence

Directly impacts quality, safety, and reliability of end products

Risk Reduction

Prevents costly recalls, rework, and equipment failures

Smart Investment

Quality air systems provide significant return on investment