Pumps

Should You Repair or Replace Your Diaphragm or Piston Pump?

Should You Repair or Replace Your Diaphragm or Piston Pump?

Downtime can be costly – but so can unnecessary replacements. Let us help you make the smart decision when faced with pump problems in your facility.

Warning Signs Your Pump Needs Attention

When Repair Is Your Best Option

If your pump meets these conditions, repairs are likely the most cost-effective solution:

- Pump housing and core components remain structurally sound

- Manufacturer still supports your model with available parts

- OEM rebuild kits are readily available (Especially for ARO models

- Internal wear is minimal with no significant corrosion present

- The pump operates in a stable, low-risk production environment

Aroplus is an ARO-authorised

Five-Star Pump Service Centre

We stock genuine parts and offer same-day turnarounds for many models.

When Replacement Becomes Necessary

Structural Damage

Housing shows cracks, warping, or significant chemical degradation that compromises integrity

Obsolescence

Your pump model is no longer supported by the manufacturer, making parts increasingly difficult to source

Chronic Failures

You’re experiencing repeated breakdowns despite proper repairs and maintenance procedures

Efficiency Concerns

Operational costs are rising due to excessive energy consumption or compressed air inefficiency

In these scenarios, investing in new equipment typically delivers better long-term value and reliability.

The True Cost of Pump Downtime

Labour + Parts + Lost Productivity =

True Cost

A £200 rebuild may appear cheaper than a £600 replacement – but if the unit fails again in 3 months, that repair actually costs you twice as much when considering:

- Production hours lost during each failure

- Technician time and availability constraints

- Delivery lead times for replacements

- Potential impact on downstream processes

Case Study: Small Repair, Significant Savings

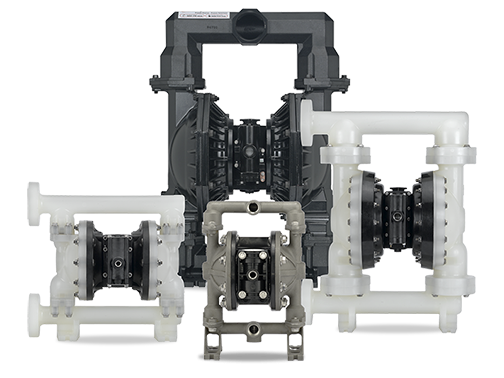

ARO Diaphragm Pump Restoration

One of our manufacturing clients faced a critical decision with their ageing ARO pump system:

- Original replacement quote: £1,850 + installation

- Our solution: Diaphragm replacement + air regulator installation

- Cost: £550 Including labour

- Result: Extended pump life by 2+ years

- Total savings: 70% versus full replacement

This targeted repair addressed the root cause of failure while maximising the usable life of otherwise sound components.

When Replacement Becomes Necessary

System Assessment

On-site evaluation of your pump systems to identify potential issues before they cause failures

Energy Surveys

Detailed analysis of your compressed air usage with actionable recommendations for efficiency improvements

OEM Repairs

Certified rebuild services using genuine manufacturer parts and factory-approved procedures

Flexible Options

Choose between on-site emergency repairs or workshop rebuilds based on your operational needs

Our technicians are factory-trained on all major diaphragm and piston pump brands, with particular expertise in ARO systems

Ready to Optimise Your Pump Systems?

Contact Aroplus Today

Whether you need emergency repairs, preventative maintenance, or advice on system upgrades, our team is ready to help.

Call: 01527 584119

Email: Aroplus@Aroplus.com