Compressors

How Air Compressors Work: A Comprehensive Guide

How Air Compressors Work: A Comprehensive Guide

Essential industrial equipment that converts electrical power into potential energy stored as compressed air. Powering everything from pneumatic tools to complex industrial processes across manufacturing and construction, air compressors represent a £35 billion global market with 5.7% annual growth.

The Basic Principles of Air Compression

The fundamental mechanism of any air compressor creates a vacuum that forces air into a compression chamber. Operating on either positive displacement or dynamic compression methods, the duty cycle completes when maximum pressure is reached.

Reciprocating piston compressors

Operating similarly to car engines, these compressors use a crankshaft to drive pistons inside cylinders. Available in single or two-stage configurations, they’re common in workshops and construction sites despite their higher noise levels.

Other Compressor Types

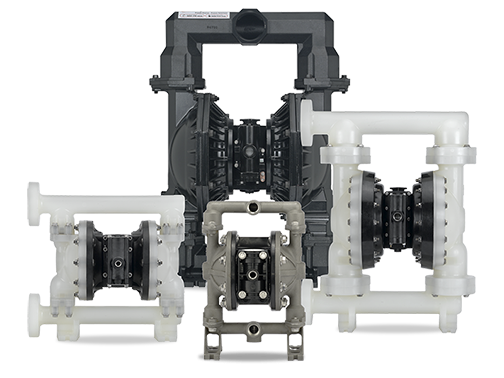

Diaphragm Compressors

Use a flexible membrane instead of a piston to compress air, providing oil-free operation ideal for applications requiring clean air such as medical and food processing.

Sliding Vane Compressors

Feature a rotor with movable vanes that trap and compress air as they rotate within an eccentric cavity, offering reliable performance with fewer moving parts.

Centrifugal Compressors

Utilize high-speed impellers to accelerate air before converting kinetic energy to pressure, perfect for high-volume, low-pressure applications in large industrial facilities.

Scroll Compressors

Employ two interleaved spiral-shaped scrolls to compress air in a smooth, continuous motion, providing quiet, vibration-free operation for sensitive environments.